How to Apply Pearlescent Pigments in Printing?

Pearlescent pigments can elevate packaging and decorative prints from ordinary to exceptional. However, achieving consistent, high-quality results requires understanding how to select and apply them correctly within different printing processes. This guide provides key parameters for successfully using pearlescent pigments in gravure, flexographic, screen, and offset printing.

01 Optical Principles and Printing Applications

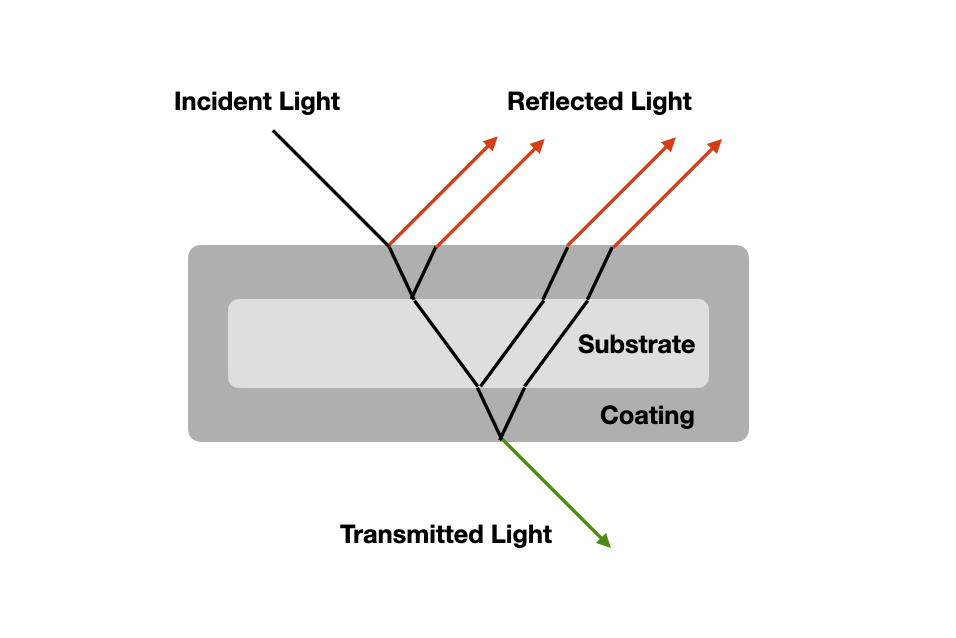

Pearlescent pigments’ Structure and Optical Mechanism

Pearlescent pigments feature a unique multi-layer platelet structure that mimics the optical properties of natural pearls. When light strikes the surface, part is reflected, and part is refracted and reflected between the layers, creating constructive interference. This produces a pearlescent luster and color shift effects with viewing angles.

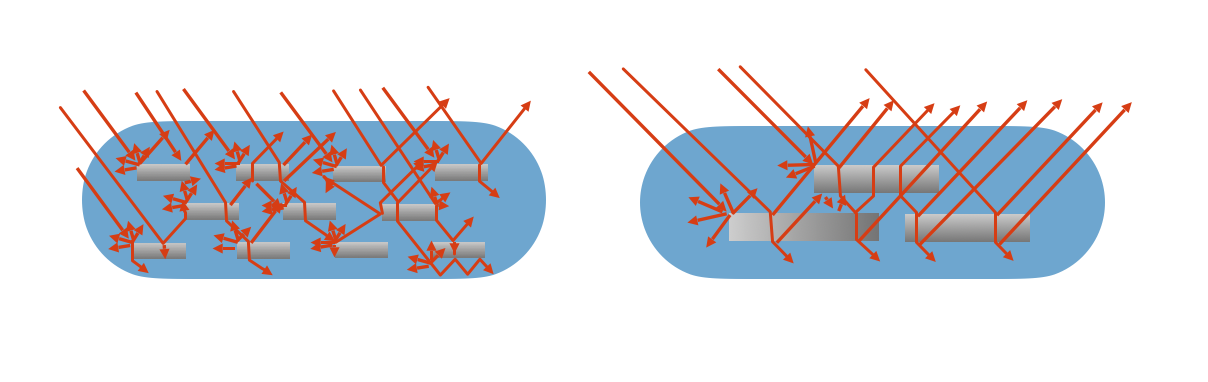

Effect of Pearlescent pigments’ Particle Size on Print Results

The particle size distribution of pearlescent pigments directly determines their optical effects and, consequently, the printing performance. Smaller particles offer higher hiding power and are suitable for pattern printing, while larger particles provide greater transparency and a stronger sparkle with less hiding, making them mostly used in large solid area printing. It is essential to select the appropriate printing process and plate/cylinder parameters based on the pigment's particle size.

02 Pearlescent pigments’ Application in Gravure Printing

Gravure printing is excellent for pearlescent effects. The screen count of the gravure cylinder is the key parameter to determines the transfer of pearlescent pigments into the substrate. Coarser pigments require lower screen count. Laser-engraved cylinders bring better pigment transfer than electro-mechanic ones.

Table 1: Gravure Cylinder Parameters vs. Pigment Particle Size

Pigment Particle Size | Recommended Screen Count (lines/cm) |

60-70 | |

50-60 | |

40-50 |

03 Pearlescent pigments’ Application in flexographic Printing

In flexographic printing, careful attention must be paid to the anilox roller selection to optimize pearlescent pigment application. It is recommended to use laser-engraved ceramic anilox rollers with hexagonal screen (60° or hachure), while employing photopolymer plates with low surface tension aids in the effective transfer of the pigments to the substrate.

Table 2: Flexographic Anilox Roller Parameters vs. Pigment Particle Size

Pigment Particle Size | Recommended Screen Count (lines/cm) |

80-120 | |

60-100 | |

50-60 |

04 Pearlescent pigments’ Application in Screen Printing、

Screen printing deposits the thickest ink films and can accommodate a wider range of pearlescent pigment particle sizes than other processes. Successful application requires a mesh opening 1.5 to 2.0 times the largest particle to prevent clogging, and a squeegee with a Shore A hardness of 60°-70°.

05 Pearlescent pigments’ Application in Offset Printing

Offset printing presents a challenge to pearlescent pigments due to its thin ink film and long ink transfer process. It is recommended to restrict pigment use to finer grades (D90 ≤ 25µm). Use a smooth rubber blanket to prevent pigment pile-up.

Summary

Successfully applying pearlescent pigments requires a precise match between particle size and your printing process. By carefully selecting plates, cylinders, and mesh according to the guidelines above, you will produce vibrant visual effects that add significant value to your products.

For more information, please contact us.